Description

Rubber Screen Plate & Rubber Sieve Panels Is Wear-Resistant Rubber Screen Plate Is a Kind Of Rubber Plate.

Embedded Metal Skeleton In The Rubber Plate

A Hole With The Same Specifications Is Evenly Distributed On It.

It Has Good Wear Resistance,

The Noise Is Small.

The Main Part Of The Vibrating Screen.

Be Mainly Used For Raw Coal Classification And Ore Sorting.

Be Widely Used In Coal Dressing And Mineral Processing Industry.

Performance Of Rubber Sieve Panels

Wear Resistant Rubber Sieve Plate (Sieve Mesh) Is Made Of Steel Plate As The Skeleton And Special Rubber As The Working Face.

Rubber Sieve Plate Has High Elasticity, High Wear Resistance, Impact Resistance, Tear Resistance And Long Service Life.

The Rubber Sieve Plate Can Be Used In Conjunction With Heavy Sieve Equipment In Mining, Metallurgy, Coking, Building Materials, Coal Preparation And Other Industries.

Characteristics Of Rubber Sieve

Application Of Wear Resistant Rubber Sieve Bend In Vibrating Sieve Equipment

First, Steel Backed Rubber Plate – Rigid Rubber:

Confecting Essentials , Increase The Tensile Stress And Hardness. Selection Technique Of Coordination Agent

1, The Use Of Strong Filler, Preferably Carbon Black, White Carbon Black And Magnesium Carbonate And So On. Talcum Powder Can Significantly Improve Hardness, But It Will Reduce The Tensile Strength.

2, Accelerators Should Be Used Together, Such As d+m And d+Dm, And Some Lime Can Also Be Added.

3, Softeners Can Be Used As Little Or Less As Possible.

4, Blending Some High Styrene Rubber And Phenolic Resin Are Effective For Improving Hardness.

Two. Steel Backed Rubber Panels – Soft Rubber:

Confecting Essentials , Improve The Raw Rubber Content, Control The Amount Of Filler And Degree Of Vulcanization. Selection Technique Of Coordination Agent

1, Appropriate Use Of Softeners, The Best For Ointment;

2, Fillers Are Soft Clay, Calcium Carbonate And Hot Cracking Carbon Black, Preferably Mixed With Appropriate Amount Of Rubber Powder.

Three. Steel Backed Rubber Mats – The Rubber With Large Tensile Strength:

Confecting Essentials, Pay Attention To The Dispersion Of Filler, Multistage Mixing And Storage, And Ensure Full Vulcanization. Selection Technique Of Coordination Agent

1, Choose Strong Carbon Black, White Carbon Black And Bai Yanhua.

2, The Amount Of Sulphur Should Not Be Too Little.

3, The Mixture Is Pure, No Impurity.

Four. Steel Backed Rubber Deck – The Rubber With Large Extensibility:

Confecting Essentials, The Rubber Content Is High And The Degree Of Vulcanization Is Shallow. Selection Technique Of Coordination Agent

1, Add More Softeners, But Pay Attention To Permanent Deformation.

2, Use Less Filler. Clay And Calcium Carbonate Should Be Used.

3, Less Sulphur

4, The Accelerator Is Used By h Or m, Dm And h.

Five, Steel Backed Rubber Media – High Resilient Rubber:

Confecting Essentials, Keep a High Content Of Raw Rubber And Fully Vulcanized. Selection Technique Of Coordination Agent

1, The Proper Use Of Soft Carbon Black, The Best For Mt, Ft;

2, Sulfur Content Is Appropriate

Six, Steel Backed Rubber Mesh – Good Wear-Resistant Rubber:

Confecting Essentials, It Is Noted That The Packing Is Evenly Dispersed And The Degree Of Vulcanization Is Appropriate. Selection Technique Of Coordination Agent

1, Match The Best Amount Of Wear Resistant Carbon Black, Followed By Saf, Isaf, Haf, Epc;

2, Fill a Large Number Of Filling Oil, Increase The Amount Of Wear Resistant Carbon Black.

3, Sulfur Content Is Generally Slightly Larger

Seven. Steel Backed Rubber Bend – Tearing Strength Of Rubber:

Confecting Essentials, The Filler Keeps Evenly Dispersed And Can’t Exceed Sulfur, Selection Technique Of Coordination Agent

1, Select The Best Amount Of Epc, Isaf-Ls, Haf-Ls

2, White Carbon Black With Carbon Black Amount Of 1/10 To 1/5.

Eight, Steel Backed Rubber Sheet – The Permanent Deformation Of The Small Rubber:

Confecting Essentials, The Degree Of Vulcanization Is a Little Deeper. Selection Technique Of Coordination Agent

1, More Use Of Filler, Less Use Of Softener

2, Magnesium Carbonate, Pottery Soil Should Be Not Used As Far As Possible.

Nine. Heat-Resistant Rubber Lined Steel Panels And Plate:

Confecting Essentials, Sulphur Free Or Sulfur Free System Vulcanization, Selection Technique Of Coordination Agent

1, No Sulfur Is Used, And 3~4 Copies Of Tmtd Are Used.

2, Zinc Oxide Will Increase Appropriately, Preferably In More Than 10.

3, Choose Heat Resistant Fillers, Such As Asbestos Powder, Black Lead Powder, Etc.

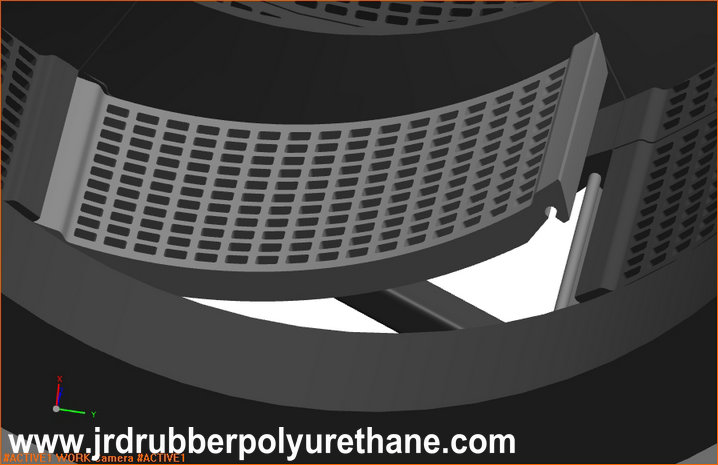

Rubber Screen Plate[/caption]

[caption id="attachment_371" align="alignnone" width="700"]

Rubber Screen Plate[/caption]

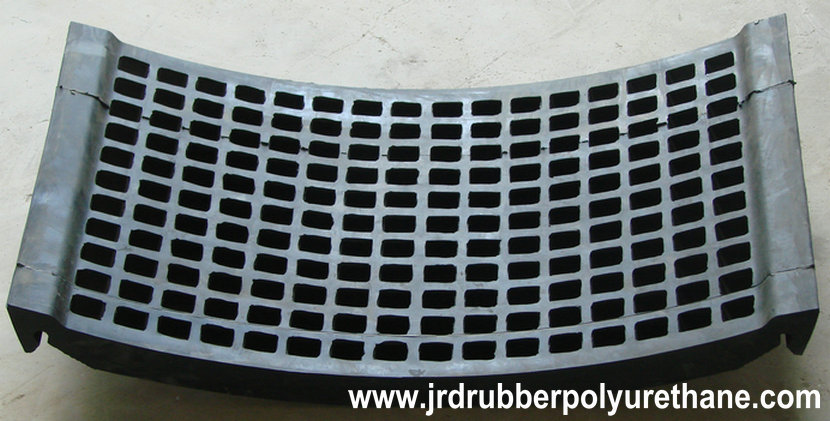

[caption id="attachment_371" align="alignnone" width="700"] Rubber Screen Mesh[/caption]

[caption id="attachment_372" align="alignnone" width="680"]

Rubber Screen Mesh[/caption]

[caption id="attachment_372" align="alignnone" width="680"] Rubber Screen Bend[/caption]

Rubber Screen Bend[/caption]