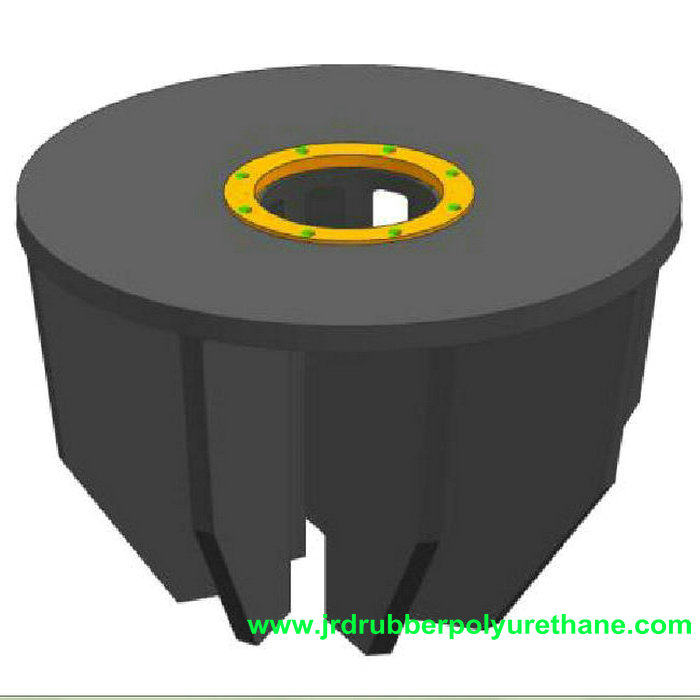

Description

Rubber Lined Pipe Is Mainly Based On The Unique Properties Of Rubber Lining Performance Of High Elasticity, High Air Tightness, Impact Resistance, Abrasion Resistance, Weather Resistance, Radiation Resistance, Chemical Resistance And Shock Absorption, Etc., Have Good Combination With Rubber And Metal Compounds, So It Is Suitable For Lining Of Rubber Chemical Equipment. So That It Can Has Steel Pipe Pressure And Rubber Liner High Abrasion , Anti Friction , Wear Resistant Characteristic.

Our Production Are Widely Used In Acid, Alkali And Salt In Various Media Transportation Pipelines, Pipes And Treatment Vessels, Reactors, Pumps, Valves, Mixers And Other Equipment To Solve The Corrosion Problem Of Pipeline Equipment.

Rubber Liner Introduction

Natural Rubber , Neoprene Rubber , Vulcanized rubber , Synthetic Rubber [ Acrylic Rubber (ACM) , Butadiene Rubber (BR) , Butyl Rubber (IIR) , Chlorosulfonated Polyethylene (CMS)/ Hypalon Ethylene Propylene Diene Monomer , Fluoroelastomers (FKM)/ Viton , Isoprene Rubber (IR) , Nitrile Rubber (NBR) , Perfluoroelastomer (FFKM) , Polysulfide Rubber (PSR) , Silicone Rubber (SIR) , Styrene Butadiene Rubber , Polychloroprene (CR)/Neoprene Rubber ]

Method:

There Are Two Methods For Rubber Lining: Hot Vulcanized Rubber Liner And Rubber Lined Bonded Inner Pipes.

Thermal Vulcanizate Lined

Rubber Is Vulcanized And Bonded On The Inner Surface Of Steel Pipe By Vulcanizing Tank Under High Temperature And Pressure.

Permissible Vulcanized Rubber

The Inner Surface Of The Rubber Wire And The Steel Pipe Axle Is Bonded By Thermal Vulcanization.

Rubber Line Adhesion Method

Through Special Vulcanizates, Make The Rubber Thread Bond Directly. Can Be Used Directly After Bonding.

Technology:

Sandblasting Of Carbon Steel Tube Frame:

Sandblasting Inside And Outside Carbon Steel Pipe Skeleton

Ensure That Both Sides Of The Pipe Frame Are Clean

The Inner Surface Roughness Of Carbon Steel Tube Skeleton Is 45-75 Microns.

Degreasing Of Carbon Steel Pipe Skeleton Surface:

Place The Sand Blasting Steel Pipe Rack On The Worktable.

Oxalic Acid Is Used To Clean The Surface Of Carbon Steel Tube Frame, Which Needs Rubber Lining.

Carbon Steel Pipe Surface Coating:

After Degreasing For 5 To 10 Minutes, Apply Adhesive A.

Make Sure That Adhesive a Is Dried And Coated With Adhesive B.

Rubber Lining For Tube:

Preheated Rubber Sheet,

Use Rubber Extruder To Finish Rubber Lining.

Paste:

Wash The Surface Of Rubber Sheet With Oxalic Acid.

After The Surface Of The Rubber Sheet Is Dried, It Is Bonded On The Surface Of The Rubber Sheet.

Vulcanization:

The First Rubber Lining Is Put Into The Vulcanization Tank For Vulcanization.

Inspection:

Test All Bonded Surfaces With a High-Pressure Spark Tester.

Ensure That All Rubber Sheet Skeletons With Steel Tubes Are Well Bonded

Where There Is No Missing, There Is No Glue.